Woodworking with Plane

08.02.2016

A plane is a carpentry tool designed for shaping wood. It is used for flattening, thinning and polishing the rough wooden surfaces.

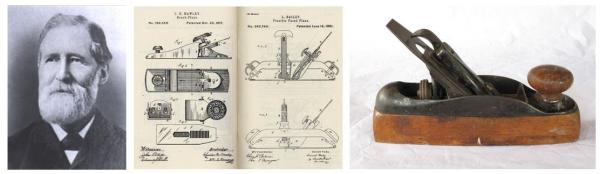

Tools for flattening wood were used since BCE. The first modern plane was made by Leonard Bailey, in the sixties of the nineteenth century, which was later produced by a renowned tool making company – Stanley.

The planes are divided into electric and hand planes. Hand planes consist of 4 basic parts:

- Sole is a metal cutter which slides over the surface of the wood and evenly slices thin shavings, which creates a smooth surface.

- A wooden wedge is a part that, with its conical shape, always keeps the sole in the same level against the body of the plane.

- The knob is a handle located on the front of the plane. Its ergonomic shape facilitates the use.

- The body of the plane varies depending on the purpose, and it can be short, for short work pieces, long, for long work pieces, and thin, for making different grooves in construction carpentry.

Working with electric plane is much easier. A set of very sharp blades along with the constant rpm enables flattening even when you are working with hard wood.

The blades are located on cylindrical holders, which are connected to the motor by a belt. Rpm of the blades is around 15000. As for the width of planning, it is defined by the length of the blade, which is usually 82 mm. The thickness of the layer shaved is adjustable and can be up to 5 mm.

Electric planes have a solution for ejecting the shavings in little textile bags, and there is an option to, instead of a bag, you attach a vacuum cleaner to the plane, so it can suck the shavings.

Check out this interesting video we prepared for you, and to see our offer of electric planes click here.

If you would like to stay up to date, please sign up for our mailing list here.